On Monday, the 9th of October, the painting of the shingles over the log side of the Stone House began. In our post titled “Roof Completed Over the Stone Side” from December of 2021 we addressed the historical and practical reasons for painting the shingles on the roof over the Stone House. In this article we will discuss the mixture of paint and copper naphthenate we are using to coat and preserve our shingles.

The base of this paint is Ottosson Linseed Oil Paint in the Iron Oxide Minimum color. The preservative qualities of linseed oil when applied to wood have been known for centuries. It seals the grain, repels water, and protects it against the harmful impacts of humidity and dirt. At the same time it allows the wood to breathe and acts as a repellant to insects and fungi. Linseed oil is extracted by pressing the dried, ripened seeds of the flax plant. Until the mid-twentieth century when synthetic resin, acrylic, and latex paints become more available, linseed oil-based paints were the ones most commonly used for coating wood surfaces. Linseed oil paint should not be confused with paints that used lead oxide as a pigment and as an ingredient for wood preservation. Lead paint is a whole other topic which we will not discuss here. One of the greatest benefits of linseed oil-based paints is longevity. It can last fifteen or more years without maintenance. It does have some limitations and drawbacks, but for our purpose of coating and preserving hand-split red oak shingles, it is truly a remarkable product. For more on linseed oil paint see “Linseed Oil Paints and Mastics Applications and Limitations” by Peter Kaczmar on the buildingconservation.com website, which is maintained by Cathedral Communications Limited in Tisbury, Wiltshire, United Kingdom.

The other ingredient in our paint is copper naphthenate. Sometimes nicknamed CuNap, it is a wood preservative that makes it less palatable to wood-destroying organisms. Naphthenate is one of the carboxylic acids naturally occurring in crude oil, and CuNap is the copper salt of naphthenic acid. It is what the greenish tint in pressure-treated wood comes from. As we have said previously, it is a modern compromise to help ensure the longevity of our very expensive split-wood shingle roof.

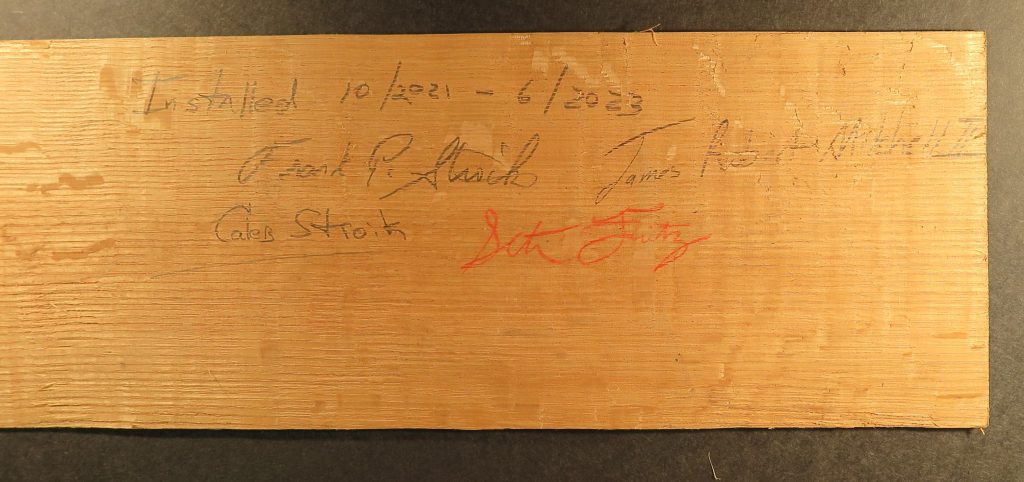

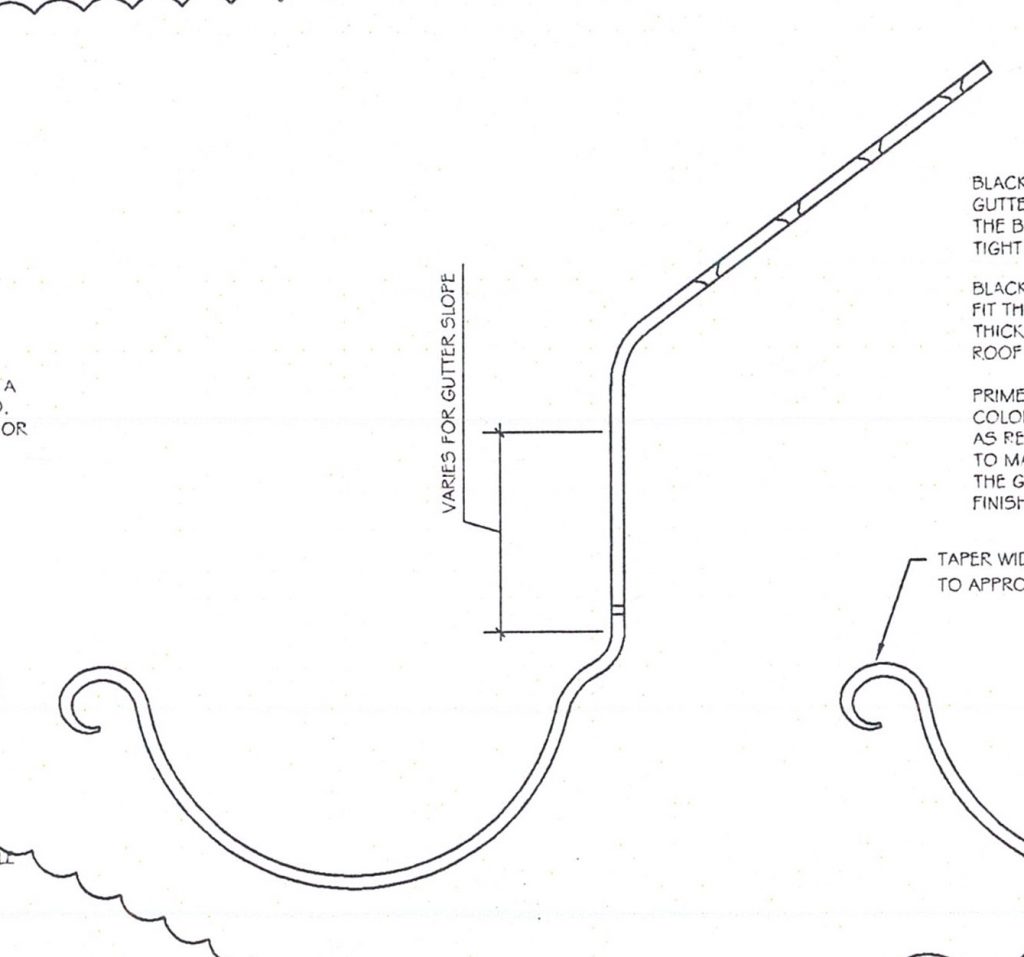

The formula we use to mix these two ingredients was given to us by our consultant, Mr. James Huston, who is retired from the Pennsylvania Historic and Museums Commission. Mr. Huston had years of experience in his career installing and caring for side-lap shingle roofs like the one over the Stone House. The mix we are using is one part copper naphthenate to around three parts of linseed oil paint. This ensures that the red oxide color is not diluted or made to appear less like the red oxide paints used historically to coat wood-shingle roofs in the eighteenth and nineteenth centuries. We are applying two coats to the roof over the log side and one fresh coat to the roof over the stone side. The stone side roof had received two coats shortly after it was installed in 2021. With the shingles over both sides of the house painted, our next step will be to install the gutters. After that we will begin the final phases of the exterior restoration of the house. We hope they will go more quickly than this roofing phase has gone. Thanks is extended to our supporters for their patience.