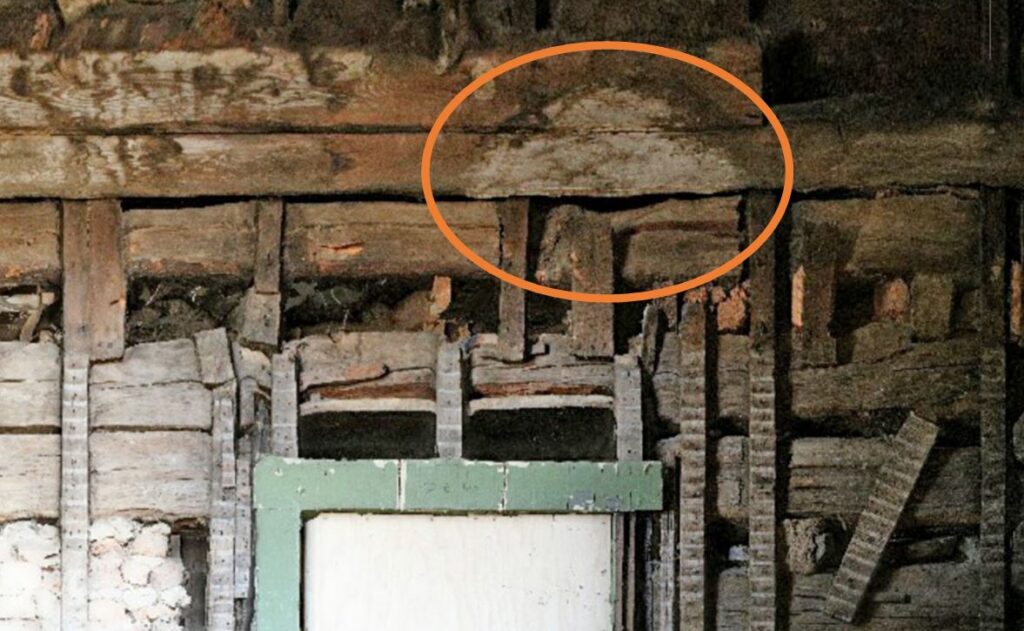

The questions we have struggled to answer as we develop the exterior restoration plans for the Stone House concern design details. Most of the time the original evidence was destroyed long ago, and we are only left with surviving examples in other structures of the period or historic images. Sometimes we get lucky. We previously have discussed the miraculous survival of the beaded weatherboards attached with original hand-forged nails under the roof of the circa 1869 shed addition behind the log side of the house. They told us how the log side of the house was sided in the 1830 period. Those weatherboards were coated in whitewash, except in one area above the rear doorway in the northeastern corner of the log addition. There the whitewash had been eroded away, leaving the outline of the apex of a gable roof for a porch that once covered the doorway beneath. (See area circled in image below.) We plan to reconstruct the porch based on this evidence. One of the design detail questions we have had to answer is what the posts for this porch roof looked like.

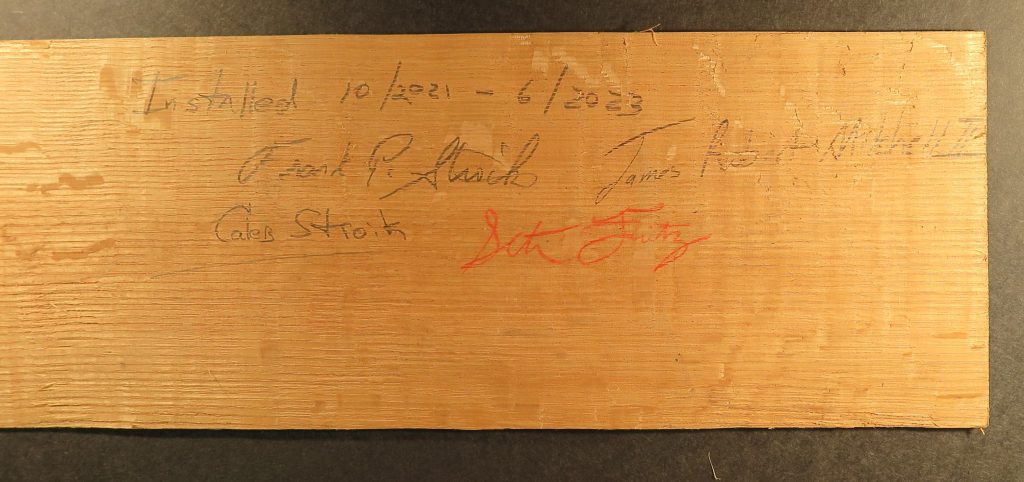

Here is another example of how we got lucky. While we were carefully dismantling the shed addition behind the log side of the house, we discovered that an old porch post had been recycled and used as a wall stud in that shed addition. (See image below.) It appears that when they demolished the rear porch to make way for the shed addition, the builders took one of the posts from the porch and incorporated it in the north wall of that addition next to a window opening. This porch post is approximately 3.8125 inches square with round beaded corners. While many of the other aspects of the design of this porch behind the log side of the house will be conjectural, we will be able to reproduce our period porch posts based on this original one that miraculously has survived.

We also have reason to feel fortunate about the second floor windows for the log side of the house. The original six-over- six pane double-hung sash windows were featured in a late nineteenth-century photograph of the log side of the house. (See image below.)

As we have studied the six-over-six pane double-hung sash windows that are installed in the garage next to the log side of the house (see image below), we have come to the conclusion that they originally came from the second floor of the log side of the Stone House. The windows that currently are installed in the second floor of the log side of the house date to the middle of the twentieth century. It appears that when the Argenbrights installed the current windows, they reused two sets of the older windows in the front of the their garage next door. These old window sashes, with their remaining old wavy glass panes, will be removed and safely stored. We will then use them as models for the new reproduction second floor windows on the log side of the house.